When running a restaurant, the design and production of your menu book is a critical cost consideration that should not be overlooked. One of the first questions to ask is whether waterproofing and durability are necessary. This depends on your menu’s usage environment and frequency of handling. If long-term resilience is a priority, materials like heat-pressed PVC offer full waterproof protection and are ideal for high-traffic settings.

Why Is Waterproofing Important?

Here are common scenarios where waterproof menu books are essential:

- Drink Bars & Cocktail Lounges

Tables often accumulate condensation, spilled ice, or dripping glasses. Without waterproofing, menus can wrinkle, stain, or warp—damaging both appearance and longevity. - Outdoor Restaurants & Terrace Seating

Exposure to sunlight, rain, and humidity can quickly degrade unprotected menus. Waterproof materials like heat-pressed PVC resist weather changes and help maintain cleanliness. - Family-Friendly & Kid-Oriented Venues

Spills are inevitable. Waterproof menus are easy to wipe clean and less prone to damage, making them ideal for child-friendly environments. - Seafood Restaurants & Market-Side Eateries

Wet hands, seawater, and food liquids pose a risk to menu integrity. Waterproof finishes prevent absorption and discoloration, preserving a professional look. - High-Turnover Fast Food Establishments

Frequent handling leads to creases, tears, and oil stains. Durable materials reduce replacement frequency and contribute to long-term cost savings.

Recommended Production Options

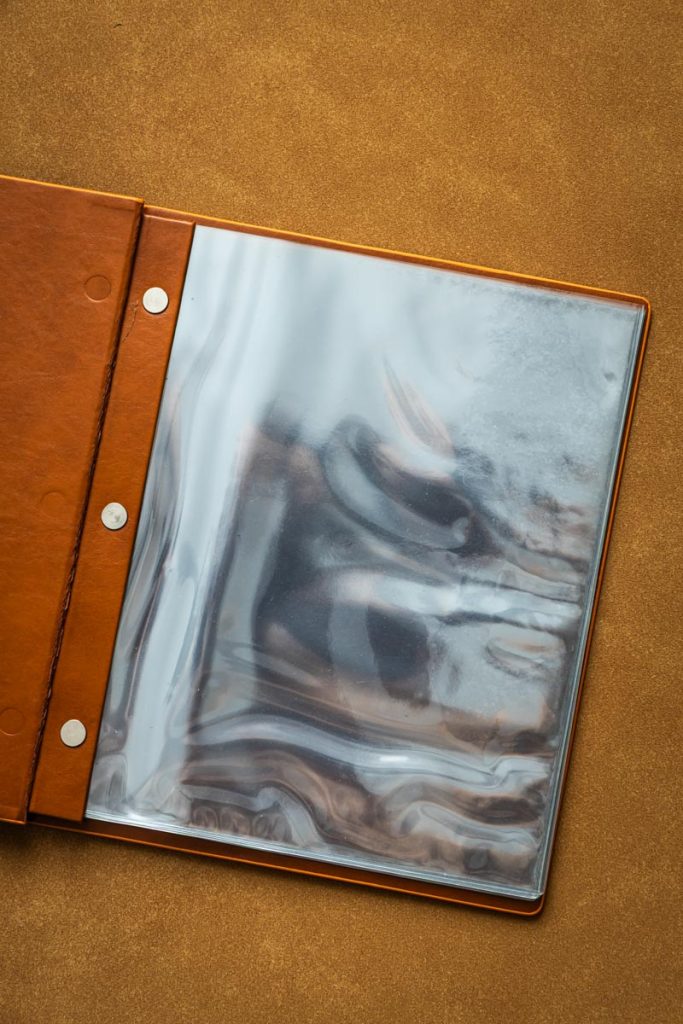

- Heat-Pressed PVC

Fully waterproof and ideal for high-use environments. - Saddle-Stitched + Waterproof Cover

A cost-effective solution for small to mid-sized restaurants. - Vinyl Cover Insert Style

Allows printed sheets to be inserted and replaced easily while maintaining waterproof protection.

Waterproofing isn’t just about material—it’s an investment in customer experience and brand image. Choose the right waterproof solution based on your restaurant type and operational needs.

From a cost management perspective, materials and finishing methods can be tailored to your budget. For example, combining saddle-stitching with PVC offers both practicality and durability at a reasonable price.

Don’t Forget: Production Lead Time Matters

Whether you’re preparing for a grand opening or updating your seasonal menu, allow sufficient time for production. Delays in delivery can disrupt operations, so plan ahead to ensure a smooth rollout.

Would you like help selecting the best waterproof format for your restaurant’s environment and budget? I’d be happy to assist.